How much do you know about the basics of brass manifold?

2022-12-12.

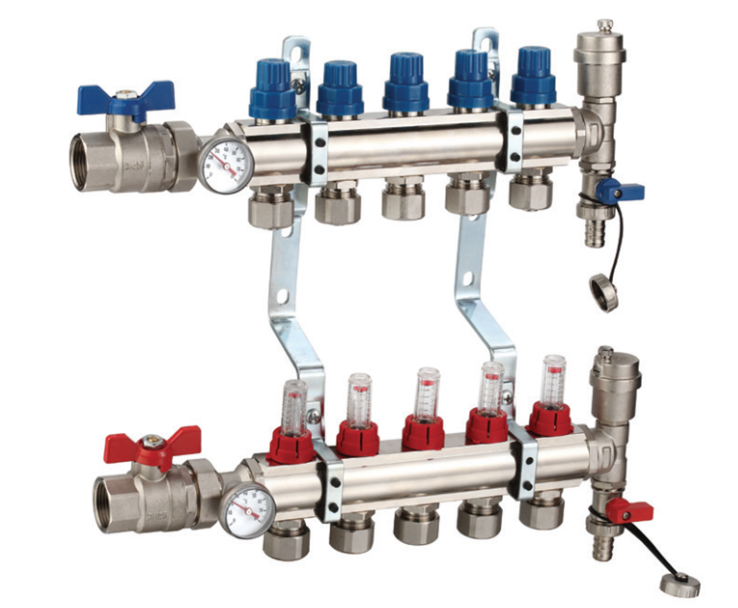

In piping systems, multiple pipes and pipe sections need to be connected to each other in order for the system to work efficiently. This is accomplished through pipe fittings, which are specifically designed to connect straight sections of pipe, as well as to connect pipes of different shapes and sizes.

There is an increasing variety of fittings in use. Different types of fittings are needed depending on the area in which they will be used. These fittings are made of various materials, such as brass, stainless steel, aluminum, steel, alloy steel, plastic, etc. Each type of fitting made of different materials has its own characteristics, features and advantages. In this article, we will discuss the basics of brass fittings.

What are the different processes involved in the production of brass manifold?

There are many processes involved in the manufacture of high quality brass manifold. The following are the most common processes involved in their production:

1. Evaporation model casting: As the name implies, evaporation technology is used for this casting process.

2. Centrifugal casting: This casting technique is most common in the manufacture of thin-walled cylinders. The centrifugal casting process is also known as the rotary casting process.

3. Continuous casting: In this casting process, the molten metal solidifies, which helps them to obtain the final finish. Continuous casting process is also known as casting.

4. Die casting: This is another metal casting process. In this process, molten metal is passed through a mold under high pressure.

What components are needed for brass manifold?

Brass manifold use many components. What are these components? Please read on to find out.

1. Couplings: Couplings are components used to connect two pipes. You can get these components in different lengths and sizes.

2. Nipple: A nipple is basically a tube. It is used to connect two fittings and is most commonly used in piping solutions. The assembly is made of copper or chlorinated PVC.

3. Tee: Tee is another important pipe fitting used to provide a steady flow of any liquid.

4. Reducer: When you want to connect two pipes of different widths. In this case, use the reducer.

5. Elbow: This part has the shape of a human elbow. It is used to change the direction of the pipe by 45° or 90°.

6. Cross: As the name implies, this component has a cross shape with four branches in opposite directions. One of the four crosses is used as the inlet, while the remaining three branches are used as the outlet.

7. Union: During maintenance, fixture or replacement, the pipe needs to be disconnected. There is also a component for this purpose. The union is a component used to disconnect the pipe when needed for the above purpose.