Safety issues of base station

In various industries, safety in production and equipment safety are always prioritized. In the context of interior decoration, ensuring the safety of personnel is an aspect that deserves careful consideration. First, let's talk about our other products. For instance, our thermostats have a shield behind the circuit to prevent any issues; the actuators have clips at the wire termination points, preventing safety issues caused by scattered copper wires. However, when it comes to our central control box, it still gives off a feeling of insecurity, and it doesn't seem to meet international safety standards during installation.

To address safety concerns, our engineers have referred to the safest products available internationally and, combining the product’s functionality and cost, have made significant upgrades. First, we investigated when safety issues are most likely to arise. It’s not typically during installation, as underfloor heating installation requires professional installers who are aware of safety and will not casually install with power on. The main problems occur during personal maintenance.

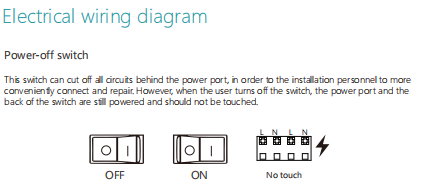

In this regard, many times maintenance is advised to be done after the power is turned off, but some daring or overly confident operators may attempt repairs or checks while the power is still on. To address this, we remind customers to ensure power is turned off during maintenance. Additionally, we have added a switch so that, apart from the L and N terminals that carry power, all other wiring connections between the thermostat and the actuator are de-energized.